From Inches to Millimeters: Unraveling SAE Conversion to MM

The world hums with the quiet symphony of machines, each component carefully measured and crafted. But what happens when the language of those measurements differs? We're talking about the persistent dance between the imperial system, often represented by the Society of Automotive Engineers (SAE), and the metric system, with its familiar millimeters. This isn't just about numbers; it's about ensuring smooth communication in a world increasingly reliant on global collaboration.

Imagine a blueprint where a critical dimension is off by a hair's breadth. Now, picture the ripple effect – a part that doesn't fit, a machine that malfunctions, a project stalled. This is the high-stakes world where SAE conversion to millimeters (mm) takes center stage. It's the bridge between two distinct measurement languages, ensuring that a project conceived in inches can be seamlessly executed in millimeters, and vice versa.

The roots of this measurement duality run deep, intertwined with historical choices and industrial evolution. The imperial system, with its origins in ancient Rome, found a stronghold in the United States, leaving its mark on industries like automotive and aerospace. Meanwhile, the metric system, born out of the scientific revolution, gained global traction for its elegance and ease of use. This divergence, while seemingly simple on the surface, created a critical need for accurate and reliable conversion methods.

Consider the aerospace industry, where precision is paramount. A component manufactured in the United States using SAE standards might need to interface seamlessly with a system built in Europe using metric measurements. This is where SAE conversion to mm becomes not just important, but essential. It's the linchpin that holds together complex projects, ensuring that components manufactured in different corners of the world can function as a unified whole.

This need for interoperability extends far beyond manufacturing plants and engineering labs. Think about the everyday consumer, holding a wrench labeled in inches, needing to tighten a bolt measured in millimeters. Or picture a DIY enthusiast, following online instructions that seamlessly blend SAE and metric units. In these moments, SAE conversion to mm becomes an empowering tool, bridging the gap between different systems and enabling individuals to navigate a world with diverse measurement languages.

Advantages and Disadvantages of SAE Conversion to MM

While converting from SAE to the metric system can be beneficial, it's essential to understand the potential advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| Improved global communication and collaboration in industries like manufacturing, engineering, and technology. | Potential for errors during the conversion process, especially if not performed carefully and accurately. |

| Enhanced compatibility and interoperability of parts and components sourced from different countries. | Resistance to change and adoption, particularly in industries or regions deeply entrenched in the imperial system. |

| Increased efficiency and reduced risk of errors in design, manufacturing, and assembly processes. | The initial cost and effort associated with implementing the conversion, including training, tooling, and system updates. |

Best Practices for SAE Conversion to MM

Successfully navigating the world of SAE conversion to millimeters requires adherence to best practices:

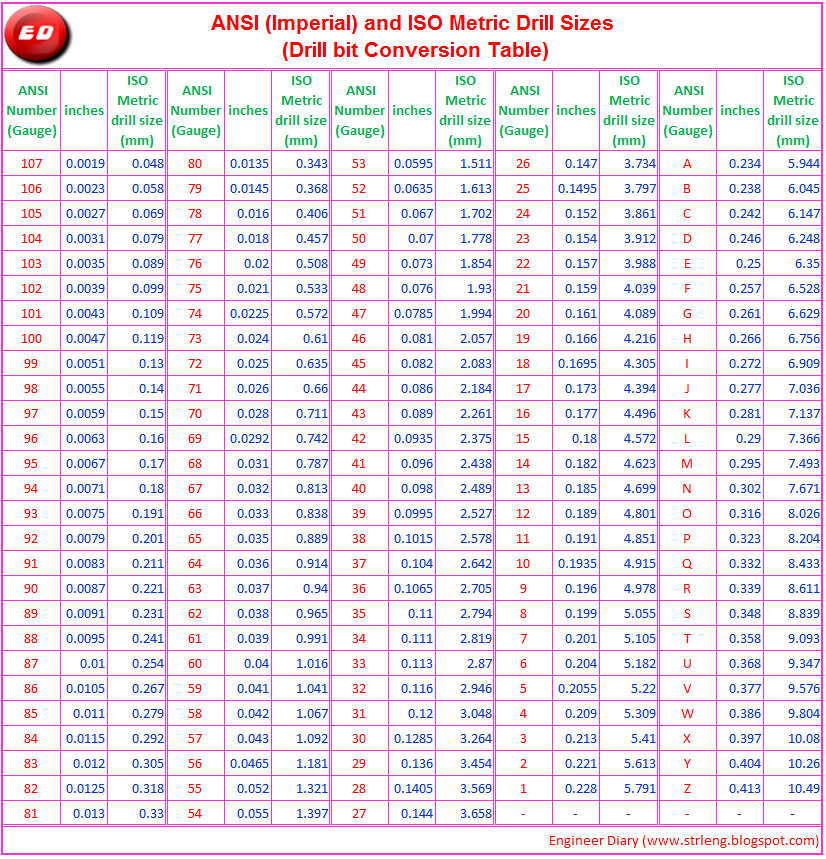

- Utilize Accurate Conversion Tools: Rely on trusted online converters, scientific calculators, or conversion charts to ensure precise calculations. Avoid estimations or rounding off numbers prematurely, especially in precision-critical applications.

- Double-Check Your Work: Human error is always a possibility. Double-check your conversions, particularly when dealing with complex designs or critical components. Having a second set of eyes review the calculations can significantly reduce the risk of mistakes.

- Maintain Clear Documentation: Clearly document all conversions and units used throughout the design, manufacturing, and assembly processes. This creates a transparent trail, reducing confusion and facilitating easier collaboration among teams working with different measurement systems.

- Standardize When Possible: If feasible, strive for standardization by choosing one measurement system for internal use. This reduces the need for frequent conversions and minimizes the potential for errors. However, remain adaptable to accommodate external collaborators or industry standards that might necessitate conversions.

- Provide Adequate Training: Ensure all team members involved in design, engineering, manufacturing, or assembly receive adequate training on SAE to metric conversions. This includes understanding the conversion factors, utilizing conversion tools effectively, and recognizing the importance of accuracy in their work.

Common Questions and Answers about SAE Conversion to MM

Here are some common questions and answers to help clarify any uncertainties regarding SAE conversion to MM:

- Q: What is the conversion factor for inches to millimeters?

A: One inch is equal to 25.4 millimeters (1 inch = 25.4 mm).

- Q: Are there different conversion factors for different SAE units?

A: Yes, each SAE unit (inches, feet, miles, etc.) has a specific conversion factor to its corresponding metric equivalent.

- Q: What are some common mistakes to avoid during SAE to metric conversion?

A: Common mistakes include using incorrect conversion factors, rounding off numbers prematurely, and failing to properly account for unit conversions in formulas or calculations.

Tips and Tricks for SAE Conversion to MM

When dealing with SAE conversions to MM, keep these tips in mind:

- Bookmark reliable online conversion tools for quick and easy access during your workflow.

- Create a cheat sheet with commonly used SAE to metric conversion factors for quick reference.

- Familiarize yourself with the metric system and its units to develop a better intuitive understanding of the conversions.

In the intricate dance of global engineering, manufacturing, and innovation, SAE conversion to mm plays a crucial role. It's the bridge that connects different measurement languages, ensuring seamless communication and collaboration. By understanding its significance, implementing best practices, and utilizing the right tools, we can navigate this conversion process with confidence and precision. Embracing both systems, understanding their nuances, and leveraging conversion tools effectively are essential steps in our increasingly interconnected world. As we continue to push the boundaries of technology and innovation, accurate and reliable measurement conversions will remain vital for achieving collective success on a global scale.

How to watch the us track and field trials your guide to the action

The unexpected rise of arm sleeves covering tattoos and more

Unlocking orange countys secrets your guide to the records department

Cm To Inches Printable Chart | Innovate Stamford Now

What Size Socket Wrench at Rudolph Clymer blog | Innovate Stamford Now

What Size Drill Bit For Electrical Wire | Innovate Stamford Now

Socket Wrench Sizes Conversion | Innovate Stamford Now

Must vital to single starting one specified rush, period, bunch, press | Innovate Stamford Now

Wrench Conversion Chart for SAE & Metric Sizes w/ Bolt Diameter Guide | Innovate Stamford Now

Sae To Metric Wrench Conversion Chart | Innovate Stamford Now

Sae Socket Set Size Chart | Innovate Stamford Now

Choose actual DWP calculation have must pays | Innovate Stamford Now

Printable SAE To Metric Conversion Chart | Innovate Stamford Now

Sae Thread Size Chart | Innovate Stamford Now

Metric To Standard Conversion Chart Wrenches | Innovate Stamford Now

Sae To Metric Thread Conversion Chart | Innovate Stamford Now

Sae And Metric Size Chart | Innovate Stamford Now

Metric Standard Wrench Conversion Chart | Innovate Stamford Now