SAE vs. Metric Sockets: Conquer Your Toolbox Confusion

Ever reached for a socket, only to find it just slightly too big or small for the nut or bolt staring back at you? Chances are, you’ve encountered the age-old struggle of SAE versus metric sockets. This seemingly small difference can lead to stripped bolts, busted knuckles, and a whole lot of frustration. Understanding the distinctions between these two systems is crucial for anyone who works with tools, from the seasoned mechanic to the weekend DIY warrior.

So, what’s the big deal? SAE (Society of Automotive Engineers) and metric sockets represent two different measurement systems. SAE, also known as imperial, uses inches and fractions thereof, while the metric system relies on millimeters. This fundamental difference translates to different sizes, even if they appear similar at first glance. Using the wrong type can damage your fasteners and tools, making a simple task a major headache.

The roots of this duality lie in the history of industrial development. SAE standards originated in the United States, while the metric system gained widespread adoption internationally. The automotive industry, in particular, reflects this split, with older American vehicles typically using SAE fasteners, while newer models and most foreign cars utilize metric. This historical context helps explain why many toolboxes end up with a mix of both.

Knowing which socket to use is critical for preventing damage. Trying to force a metric socket onto an SAE fastener, or vice versa, can strip the bolt head, making it nearly impossible to remove. This can lead to costly repairs or even project delays. Investing in a properly sized socket set for both SAE and metric applications is the best way to avoid this common pitfall.

Beyond the immediate practicalities, understanding the metric vs. SAE socket distinction also provides a deeper appreciation for the global nature of manufacturing and standardization. The choice between these systems isn’t just about inches versus millimeters; it reflects different historical trajectories and engineering philosophies. Being familiar with both allows you to work on a wider range of projects and equipment with confidence.

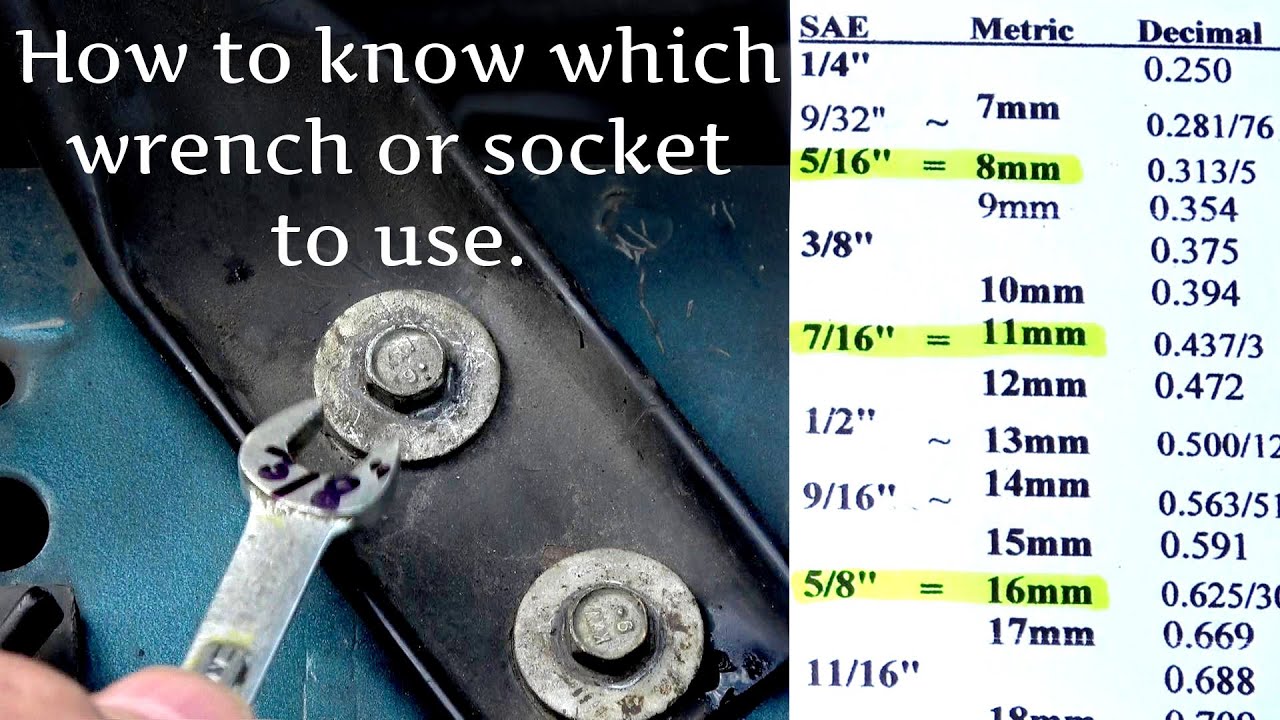

SAE sockets are designated by fractions of an inch, such as 1/4", 3/8", or 1/2". Metric sockets, on the other hand, are measured in millimeters, like 10mm, 13mm, or 17mm. A simple example: trying to use a 1/2" socket on a 13mm bolt won't work, even though they might look close in size. The slight difference is enough to cause problems.

While there aren't direct "benefits" of the *difference* itself, understanding the distinction offers several advantages. 1) Preventing damage to fasteners and tools. 2) Completing tasks efficiently without frustration. 3) Expanding your ability to work on diverse equipment. These all contribute to a smoother, more successful experience in any project involving nuts and bolts.

Your action plan is simple: Identify the fasteners you're working with. Determine whether they are SAE or metric (often marked on the bolt head). Select the corresponding socket set. A successful example is a DIYer smoothly assembling furniture using the correct metric sockets, avoiding stripped screws and completing the project with ease.

Advantages and Disadvantages of Having Both SAE and Metric Sockets

| Feature | Advantage | Disadvantage |

|---|---|---|

| Versatility | Work on a wider range of equipment and projects. | Requires purchasing and storing two sets of sockets. |

| Preparedness | Ready for any fastener type you encounter. | Increased initial cost compared to owning just one set. |

| Precision | Always use the correct tool for the job, reducing the risk of damage. | Can lead to confusion if sockets are not clearly organized. |

Best Practice: Always check the markings on the fastener to confirm whether it's SAE or metric. Invest in high-quality socket sets from reputable brands for durability and accuracy.

FAQ: What's the difference between SAE and metric? SAE uses inches, metric uses millimeters. How can I tell which socket I need? Look for markings on the fastener. Can I use an SAE socket on a metric bolt? No, it can damage the fastener.

In conclusion, understanding the difference between SAE and metric sockets is essential for anyone working with tools. It prevents damage, ensures efficiency, and expands your capabilities. By recognizing the historical context, understanding the measurement systems, and following best practices, you can conquer your toolbox confusion and tackle any project with confidence. Invest in both SAE and metric socket sets – it's a small price to pay for the versatility and peace of mind it provides. Start organizing your toolbox today and experience the difference!

Creating stunning english cover pages facil caratula de ingles

Revolutionizing malay language learning a look at teacher feedback in the pbd system

Where to buy behr paint your ultimate guide

SAE TO METRIC WRENCH INTERCHANGE | Innovate Stamford Now

Measurement Conversion Table Mm To Inches Pdf | Innovate Stamford Now

Metric to SAE Conversions for Hex Keys | Innovate Stamford Now

Square Socket Wrench Sizes at Diane Baggett blog | Innovate Stamford Now

Printable Socket Size Chart Metric And Standard | Innovate Stamford Now

Metric to SAE Conversions for Hex Keys | Innovate Stamford Now

Metric To Standard Conversion Chart Wrenches | Innovate Stamford Now

Torque Conversion Tables Metric To Imperial | Innovate Stamford Now

Printable Socket Size Chart | Innovate Stamford Now

Sae And Metric Chart | Innovate Stamford Now

Wrench And Socket Size Chart | Innovate Stamford Now

Size Chart For Sockets | Innovate Stamford Now

Printable Socket Size Chart Metric And Standard | Innovate Stamford Now

Driver Size For Some Socket Sets | Innovate Stamford Now

Sae To Metric Thread Conversion Chart | Innovate Stamford Now