Stopping Fuel Leaks: Mastering Fuel Line O-Ring Replacement

A subtle gasoline smell. A damp spot under your car. These could be signs of a failing fuel line o-ring. Ignoring these signs can lead to dangerous leaks and potential engine damage. But don't worry, replacing these small but crucial components is often a manageable DIY task.

Fuel line o-rings create a seal between fuel line connections, preventing leaks. These small, circular rings are made of a durable, fuel-resistant material. Over time, they can become brittle, cracked, or compressed, leading to fuel seepage. Knowing how to address this issue is essential for maintaining a safe and reliable vehicle.

The history of fuel line o-rings is intertwined with the evolution of fuel injection systems. As engines became more complex and fuel pressures increased, the need for reliable sealing mechanisms became paramount. O-rings provided a simple yet effective solution, allowing for high-pressure fuel delivery without leaks.

One of the main challenges associated with fuel line o-ring replacement is accessing the fuel lines themselves. Depending on the vehicle, these lines can be tucked away in tight spaces, requiring patience and the right tools to reach. However, the importance of this task cannot be overstated. A leaking fuel line poses a serious fire hazard and can also lead to performance issues and environmental damage.

Before diving into the replacement process, it's essential to understand the different types of fuel line o-rings. While they all serve the same purpose, variations exist in size and material. Consult your vehicle's service manual to ensure you purchase the correct replacements.

Replacing fuel line o-rings offers several benefits. First, it prevents potentially dangerous fuel leaks, safeguarding you and your vehicle. Second, it improves fuel efficiency by eliminating fuel loss. Third, it can resolve performance issues related to fuel pressure fluctuations.

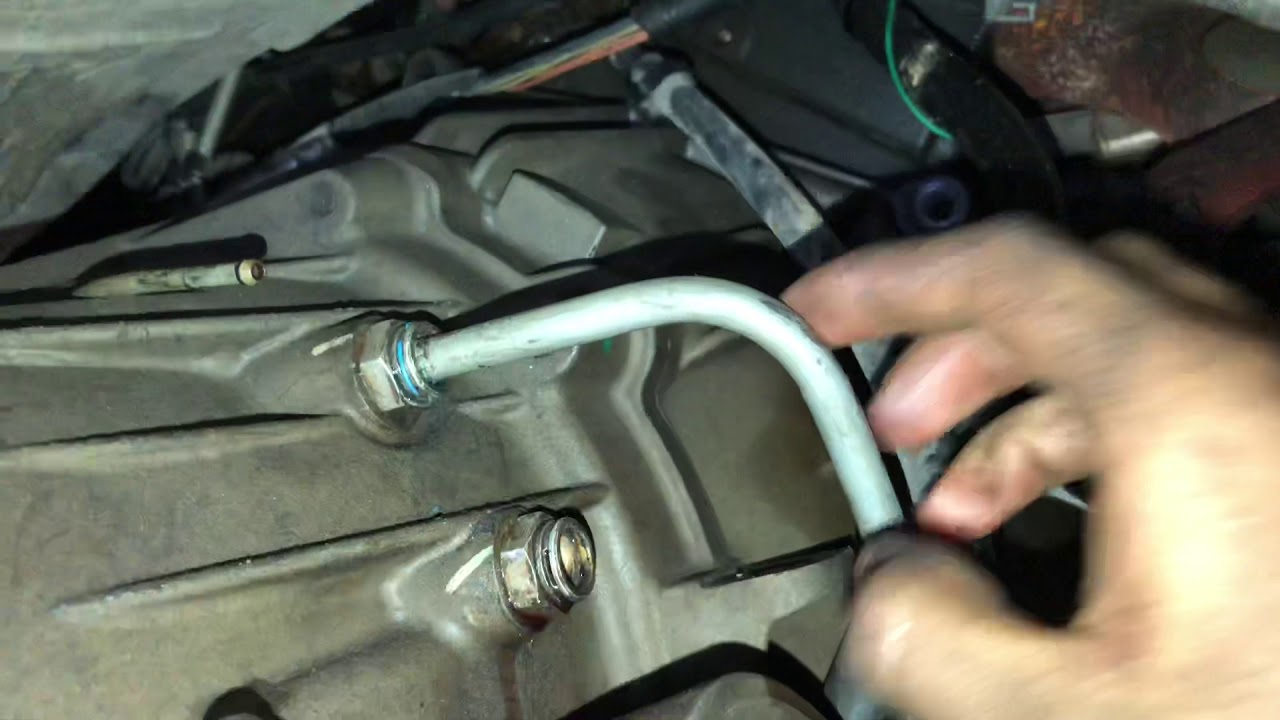

Here’s a simple action plan: gather your tools (o-ring pick set, new o-rings, fuel line disconnect tools, safety glasses, gloves), relieve fuel pressure, disconnect the fuel line, remove the old o-ring, install the new o-ring, reconnect the fuel line, and check for leaks.

Checklist: New O-rings, Fuel line disconnect tools, O-ring pick set, Safety glasses, Gloves, Clean rags

Step-by-Step Guide: 1. Relieve fuel pressure. 2. Disconnect the fuel line. 3. Remove the old o-ring. 4. Install the new o-ring. 5. Reconnect the fuel line. 6. Check for leaks.

Consult your vehicle's repair manual for specific instructions.

Advantages and Disadvantages of DIY Fuel Line O-Ring Replacement

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for fuel spills |

| Sense of accomplishment | Can be time-consuming |

Best Practices: 1. Always relieve fuel pressure before disconnecting fuel lines. 2. Use the correct o-ring size and material. 3. Lubricate the new o-ring before installation. 4. Inspect all fuel lines for damage. 5. Double-check for leaks after reconnecting the fuel lines.

Real-world examples are numerous, from a 1998 Honda Civic to a 2015 Ford F-150, o-ring failures can occur across makes and models.

Challenges and Solutions: Limited access can be overcome with the right tools. Difficult o-ring removal can be solved with an o-ring pick set. Etc.

FAQ: 1. How often should I replace fuel line o-rings? 2. What are the signs of a failing o-ring? 3. Can I reuse old o-rings? 4. What causes o-rings to fail? 5. What happens if I don't replace a failing o-ring? 6. Where can I buy replacement o-rings? 7. What tools do I need to replace fuel line o-rings? 8. How do I relieve fuel pressure?

Tips and Tricks: Use a small amount of fuel-compatible lubricant on the new o-ring. Inspect the fuel line connectors for damage. Double-check all connections for tightness.

Replacing fuel line o-rings is a crucial aspect of vehicle maintenance. This seemingly small task can prevent dangerous fuel leaks, enhance fuel efficiency, and ensure the smooth operation of your engine. By understanding the importance of these components, knowing how to identify signs of failure, and following the proper replacement procedures, you can maintain a safe and reliable vehicle. Don't underestimate the significance of these small but vital components. Taking proactive steps to maintain your fuel system will contribute to the longevity and safety of your vehicle. Addressing fuel leaks promptly not only protects your car but also minimizes the environmental impact of fuel spills. So, equip yourself with the right knowledge and tools, and take control of your vehicle’s health. Regular inspections and timely replacements are key to a worry-free driving experience.

Navigating lansing entertainment beyond the usual

Benjamin moore butter yellow the sunny side of paint

Decoding farrow and ball paint samples a comprehensive guide

Fuel Line Connect O Rings | Innovate Stamford Now

how to replace fuel line o rings | Innovate Stamford Now

Diagram 4 3 Vortec Fuel Line O Ring | Innovate Stamford Now

TBI fuel line o | Innovate Stamford Now

how to replace fuel line o rings | Innovate Stamford Now

QA Chevy 57 Vortec Fuel Line Diagrams Connectors | Innovate Stamford Now

98 Chevy 1500 Fuel Line Diagram | Innovate Stamford Now

how to replace fuel line o rings | Innovate Stamford Now

Duramax Fuel Line Diagram | Innovate Stamford Now

Ford Ranger Fuel Line Repair Kit | Innovate Stamford Now

4l60e Transmission Cooler Line Fitting Size | Innovate Stamford Now

Diagram 43 Vortec Fuel Line O | Innovate Stamford Now

About fuel line o | Innovate Stamford Now

how to replace fuel line o rings | Innovate Stamford Now

how to replace fuel line o rings | Innovate Stamford Now